Quality is top of mind, now more than ever. Fulfill the Need Installations such as SUNPLAS are hard at work on a global scale making sheets for luxury. This meticulously design process that goes into creating such premium sheets is a mix of high-tech. Series that enables us to gain a deeper insight into the background work of managing global sheet demands.

Quality:Is The Complicated Process Of Making Luxury Sheets For World Consumption:

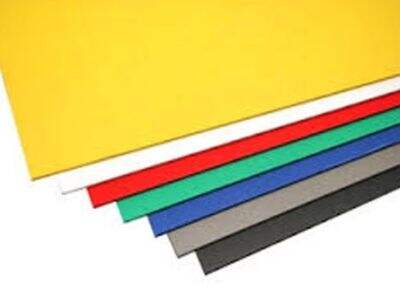

They can even be a little bit difficult to achieve, luxury sheets. This is a meticulous work and needs to be done with quality. SUNPLAS starts with the best raw materials, like Egyptian cotton or Bamboo fibers, to make our hdpe sheets soft and flexible so they can contour themselves against your skin properly. Advanced machinery is used to then meticulously weave these raw materials together and develop the ideal fabric for sheets.

Revealing the immense production processes that are required to produce premium sheets:

If the textile is now ready, it is time to produce. Our large-scale sheet production factory is equipped with big German imported machines. Inside these factories are bustling with workers cutting, sewing and finishing each high impact plastic sheets with the utmost detail. Things are on a massive scale at these operations, with hundreds of sheets being made daily all around the world to satisfy demand.

Showing How To Stay Ahead of Global Sheet Demand With Technology and Innovation

To meet the growing demand for luxury sheets, SUNPLAS always keeps pace with new technology and innovation. From automated cutting machines to computerized sewing techniques, and they are constantly striving to be more efficient and better quality products. SUNPLAS now have the capability to process frosted plastic sheets faster and more efficiently than ever before using the latest in technology, guaranteeing customer satisfaction across continents.

Sheet manufacturing behind the scenes:

Manufacturing luxury sheets is a really interesting process that few people ever get to experience or see. Extensive quality control processes are carried out at every step of the way from raw materials to finished goods to ensure that each sheet meets SUNPLAS' highest standards. Employees take pride in the fact that they are building something somebody will own and enjoy using, in every corner of the globe.

How global suppliers answer the call for more sheet material:

Worldwide demand for these sheets is high, and it takes giants like SUNPLAS to keep up with the call. This allows them to manufacture high quality luxury sheets at an incredible scale while still using technology, innovation and talent. SUNPLAS is engaged in sourcing the best materials, processing with powerful machines to every corner of customers. So the next time you roll over in bed to a lush fluffy sheet, appreciate all of that work and care- so deserving of rest.

Table of Contents

- Quality:Is The Complicated Process Of Making Luxury Sheets For World Consumption:

- Revealing the immense production processes that are required to produce premium sheets:

- Showing How To Stay Ahead of Global Sheet Demand With Technology and Innovation

- Sheet manufacturing behind the scenes:

- How global suppliers answer the call for more sheet material:

EN

EN