Understanding the manufacturing process

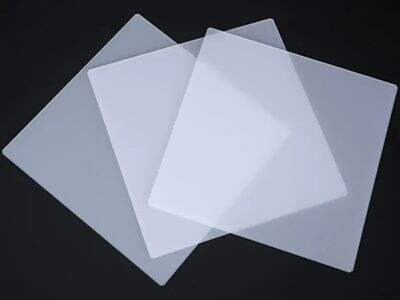

In your projects you may easily and regularly come across cast acrylic or extruded acrylic sheets. But the question is what is the difference between them. In simple terms, for knowing this thing we have a dive into how they are made

Manufacturers make cast acrylic sheets by pouring liquid acrylic into a mold and letting it harden. The process produces more uniform sheets than are possible with roll plastic, especially thin sheet made from low melt strength polymers. Extruded acrylic sheets, on the other hand, are extruded through rollers, and they have a uniform thickness. Although the speed and cost of extrusion sheets are attractive, and have some clarity and even durability constraints

Differences in strength and durability

Cast acrylic sheets are generally thought to have a higher strength and durability than extruded sheets. It's less flexible, but also considerably stronger in both impact and tensile strength: a good choice when durability is of the utmost importance. Extruded acrylic sheets are more scratch and crack prone than cast because of the manufacturing process

Clarity and transparency comparison

The most prominent difference between cast and extruded acrylic sheets is that of clarity and transparency. Generally, cast acrylic sheets offer superior optical clarity and are more resistant to yellowing with age as compared to extruded sheets. All of which makes them a favored selection for ventures where crystal clear optics are crucial, like displays and signage

Thermal forming and fabrication considerations

Cast and extruded acrylic sheets can be fabricated using common heating methods such as heat bending, enabling the design of multiple shapes and structures. Though it should be noted that thermoforming with cast acrylic can take place at a lower temperature compared to extruded sheets. This could leave the material more susceptible to warping and becoming distorted when thermally formed. Extruded acrylic sheets, meanwhile have a higher thermoforming temperature and are therefore more adaptable to complex shapes and structures

Selecting the most appropriate material for your study

Choosing which one is better suited for your project depends on the requirements that you have from it. If you need something tough, impact resistant, crystal clear in visibility and snazzy to give a glossy glow to your product than cast acrylic sheets are just the best materials for you. On the other hand, if you are more concerned about price and how easy it is to work with, extruded acrylic sheets could be one of the top choices

So in this way, cast acrylic is the best… On last words that advantages and disadvantage as well of both type of Acrylic sheet. This knowledge can help you take an educated approach to what material your project ultimately uses. Regardless you pick cast acrylic or extruded acrylic sheets, SUNPLAS is able to provide one that suits your demand

EN

EN